Our Comprehensive Restoration Services

From sanding off rust to adding new a gloss to your project, our comprehensive services cater to all your restoration needs. Immerse yourself in a world of personalized reconditioning solutions designed for bringing your machine or metal work back to life.

Services

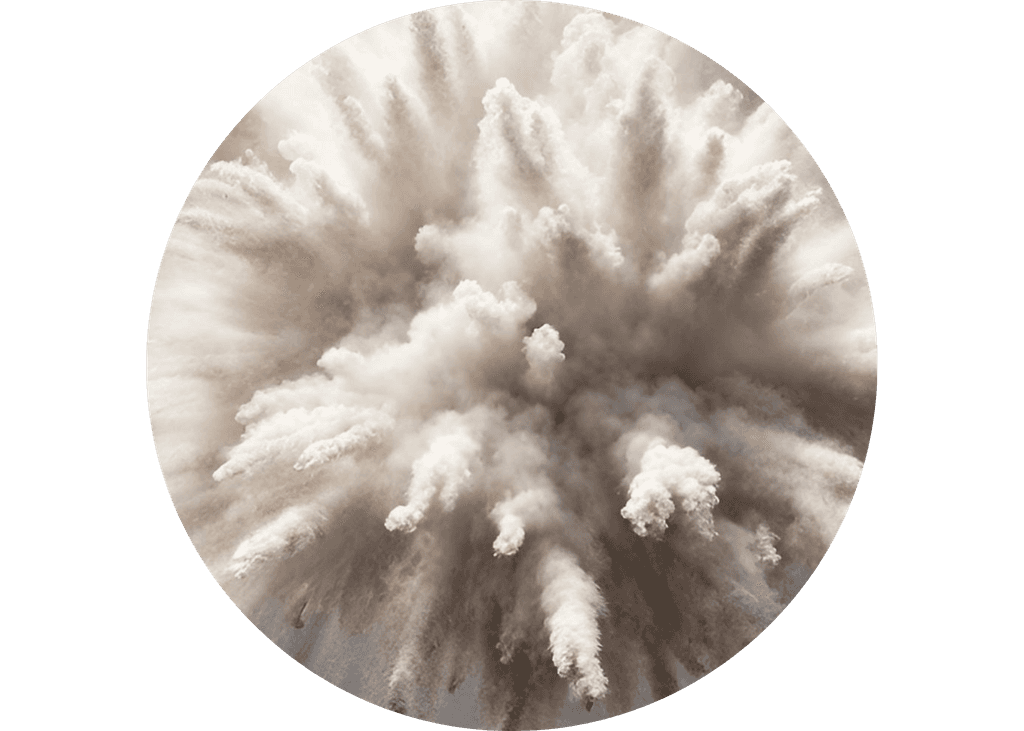

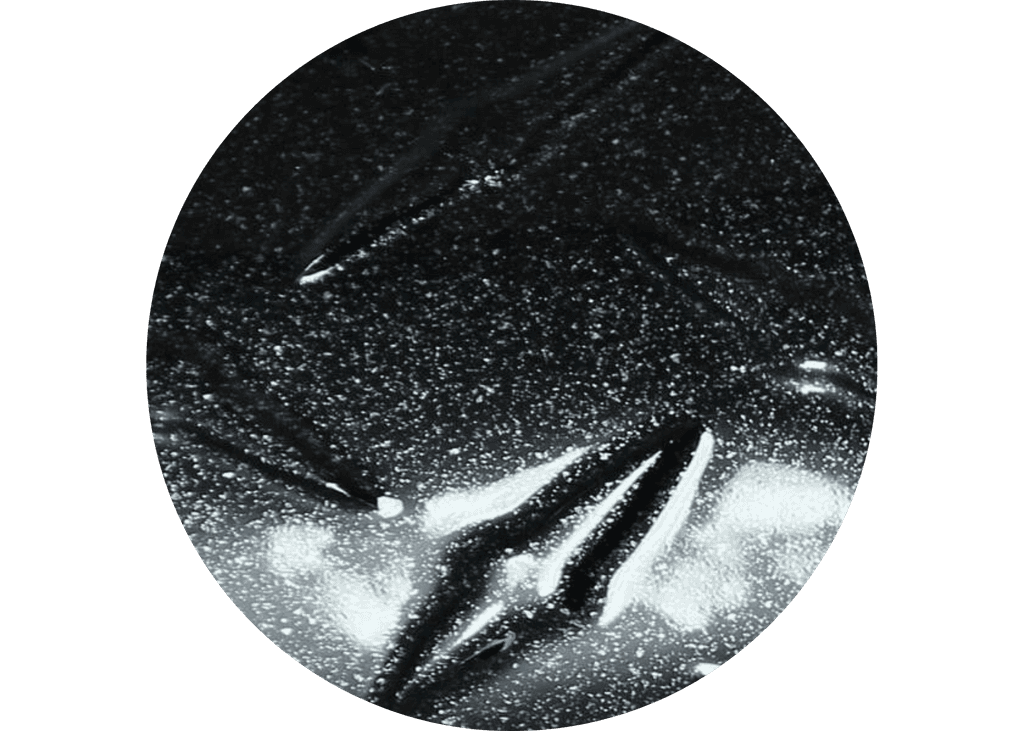

Sandblasting, Painting, & Powdercoating

Transform your project with our advanced services. From sandblasting to remove unwanted particles to powdercoating for years of protection, our expert team ensures you get quality work to help your project look as good as it did brand new.

Sandblasting, also known as dry abrasive blasting, utilizes abrasive materials to cleanse or strip contaminants from surfaces using a blasting machine. This process has shifted from traditional sand to various abrasive media due to environmental concerns. Understanding the interaction between blasting media and surface types, along with the most effective blast systems, is crucial for optimal results. In this blog post, we'll explore the diverse applications of sandblasting and its efficacy in removing robust coatings.

Originally, sandblasting involved using sand particles to remove unwanted materials from surfaces. Nowadays, sand is seldom used; instead, numerous eco-friendly alternatives are available. There is a vast array of abrasive materials suitable for cleaning or stripping coatings from almost any substrate. These include crushed glass, steel grit, aluminum oxide, garnet, plastic and glass beads, and walnut shells, each offering either a smooth finish or an anchor profile.

Equipment and Applications

Our sandblasting equipment supports virtually all available blast media, enabling a wide range of applications. With the correct media, a proficient blast nozzle, and our versatile abrasive blasting system, there are limitless restoration possibilities. Sandblasters can remove stubborn paint, rust, and contaminants from vehicles, boats, heavy machinery, and more. Here are several key applications:AntiquesToolsMetals and BrassAutomotive interiorsWood and Log HomesMarinePowder CoatingHeavy Machinery and Farm EquipmentRust and Paint Removal

Special Considerations for Different Materials

For automotive projects, dry blasting is preferred as it leaves less residue than wet blasting, which is more suited to body panels to prevent warping. Our equipment also allows for post-blasting surface treatments like priming and painting.

In wood restoration, especially log homes and wooden furniture, organic abrasives like corn cob or walnut shells are ideal. These materials are gentle on natural woods, which require cleaning every five to seven years to maintain oil-based stains.

For heavy machinery and farm equipment, dry blasting is advantageous due to the difficulty in cleaning out wet media from intricate parts. This method enhances the appearance and function of equipment with minimal effort.

Regarding antiques, the choice between wet or dry blasting depends on the object's surface complexity. Dry media is often better for intricate pieces, ensuring easier cleanup after blasting.

Conclusion and Benefits of Sandblasting

Lastly, sandblasting is a superior method for removing paint, rust, and corrosion quickly and effectively compared to manual scraping or chemical methods. In conclusion, sandblasting is a versatile technique suitable for a myriad of surface types and applications, making it an excellent entry point into the surface preparation industry. Whether tackling small residential tasks or large industrial projects, our equipment, including blast pots and mobile units, is perfectly suited for any restoration job, whether it involves traditional sandblasting, soda blasting, or vapor blasting.

Specialized & Restorative

Transform your project with our advanced services. From sandblasting, to remove unwanted particles, to powder coating for years of protection, our expert team ensures you get quality work. Our job is to make your project look like new again!

Book an Appointment

Schedule your drop-off and let us take care of the rest! Take the next step in getting your project restored and looking new again!